50-1299

50-1299 50-1299UPG

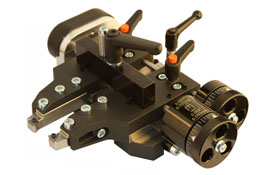

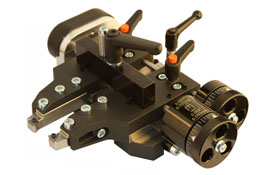

50-1299UPGOur newest cutting head, the 1250 Parallel Arm model, offers increased mass, and great usability features like adjustable tool arm length up to 100mm (can you say Peterbilt?), increased rotor thickness capability up to 50mm(Peterbilt = 45mm), and larger user facing depth knobs for improved smaller vehicle access and technician visibility.

Add the G2X MICROMETER UPGRADE, and you will be simultaneously measuring the rotor as soon as you start turning the depth knobs. Upgraded machines will display the thickness of the rotor on the DRO screen, alternately with the as cut run-out. The machine now gives the tech the two most common specs to record with no extra tools! Available only for PFM 9.2DRO, A10 Warthog, and PFM X9.

50-1299

50-1299  50-1299UPG

50-1299UPG

Most of the rotors that are thrown away can be saved and made as good as new with a Pro-Cut Rotor Matching System. Even in areas where rust is a challenge you'll find that most rotors can be machined and matched to the hub. Your customer gets a premium brake job without buying un-needed parts...and your shop makes higher profit on the job. |